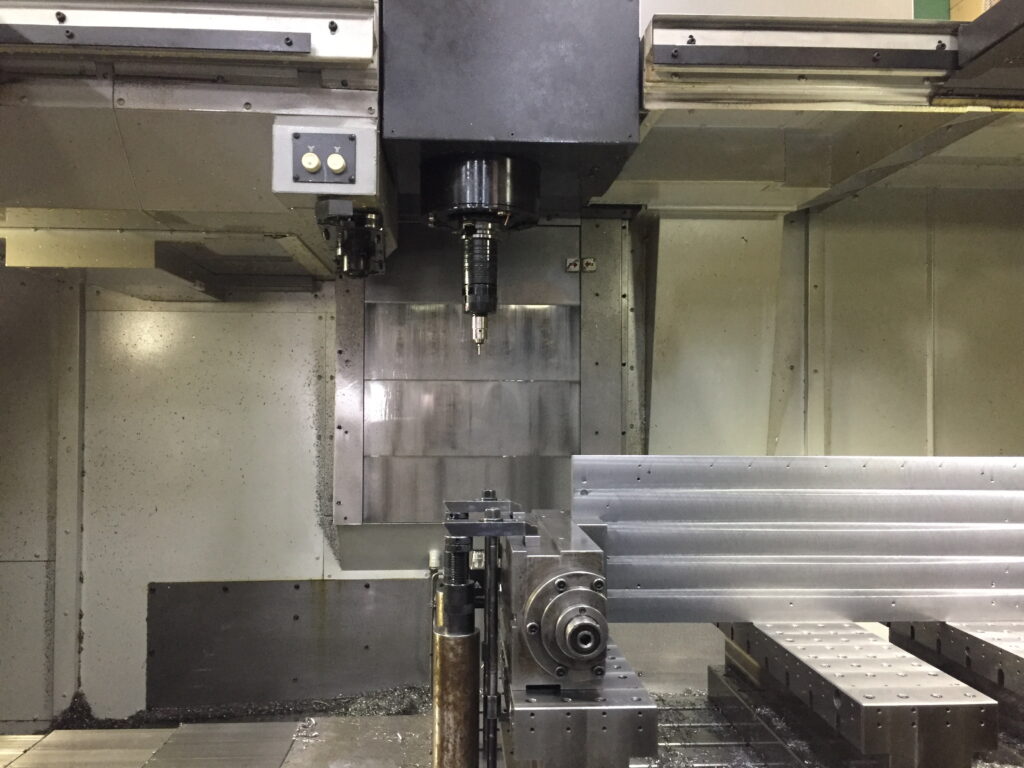

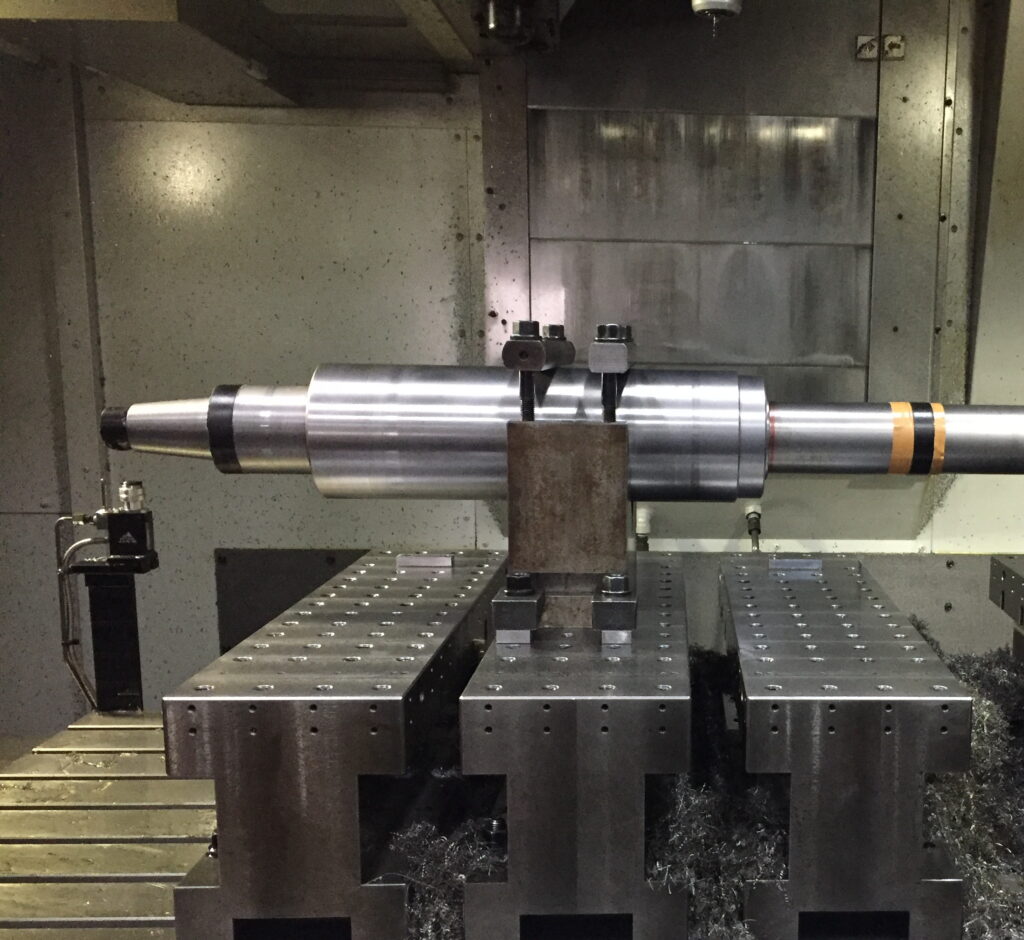

Here are some free images from a job where we used an additional axis (indexer) on a vertical machining center to perform chamfering on the inside of a cylinder using a ball end mill.

By combining a 4-axis machining center with a ball end mill, it becomes possible to achieve cylindrical internal chamfering, which is difficult with conventional machining.

Due to the unique combination of cylindrical and spherical shapes, the cut can sometimes be deeper than the data setting. Therefore, the key is to set the initial chamfer size smaller and gradually approach the final desired size.

Key Terminology for the Article

It can hold multiple tools at once, allowing it to automatically perform various operations—such as drilling, milling, and tapping—in a single setup. By strategically arranging multiple workpieces on the machine, it is also suitable for continuous, unattended operation.

By introducing a rotary table, you can perform multi-face machining with just a single workpiece setup. This significantly shortens setup times and allows for the efficient machining of complex, free-form parts that were previously difficult to produce.