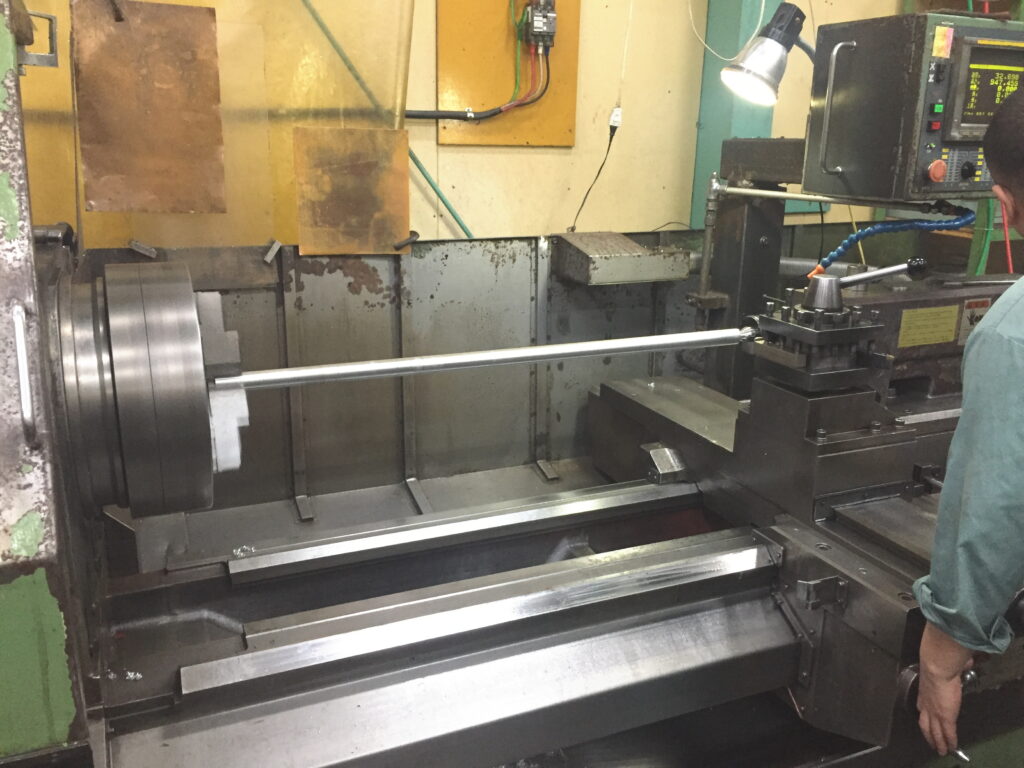

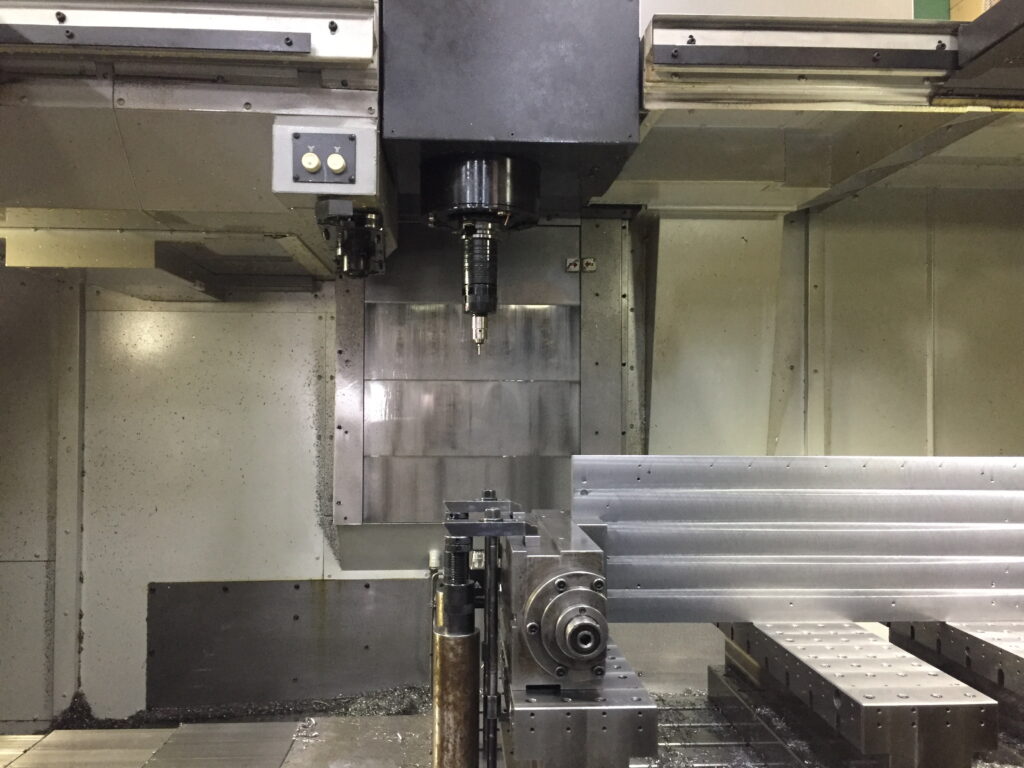

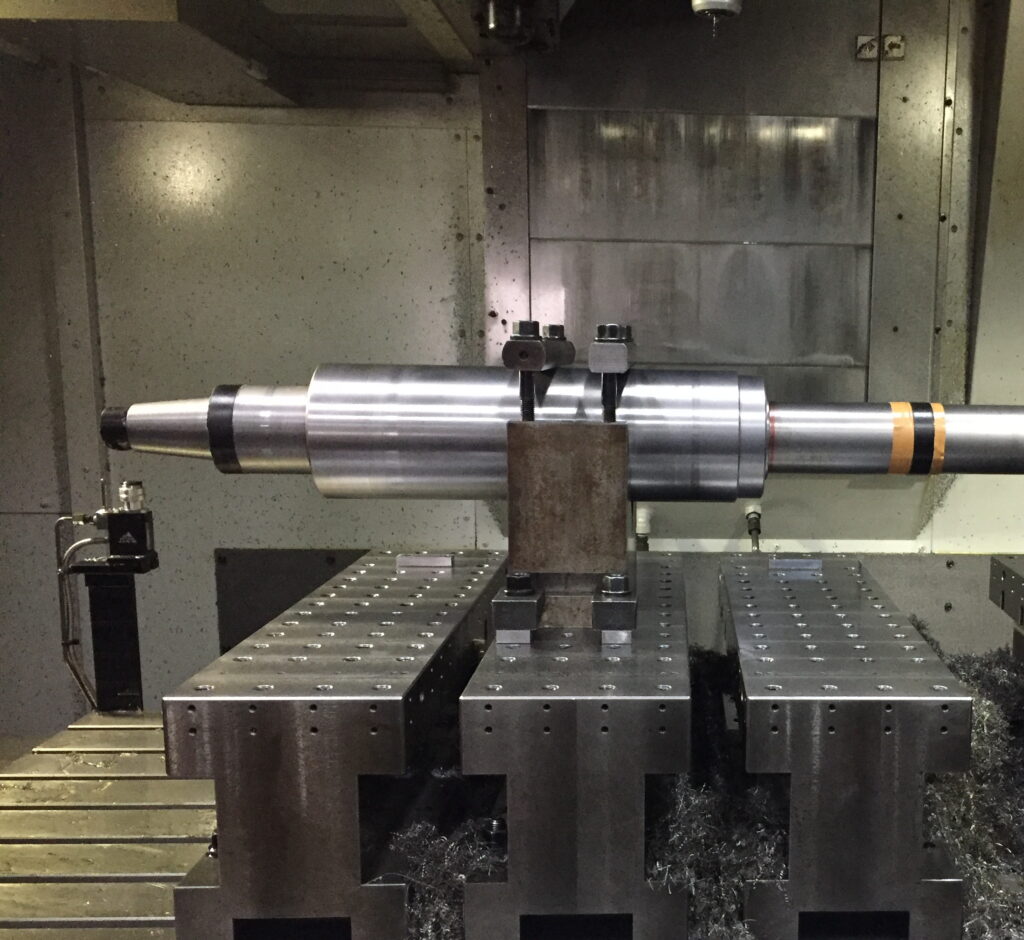

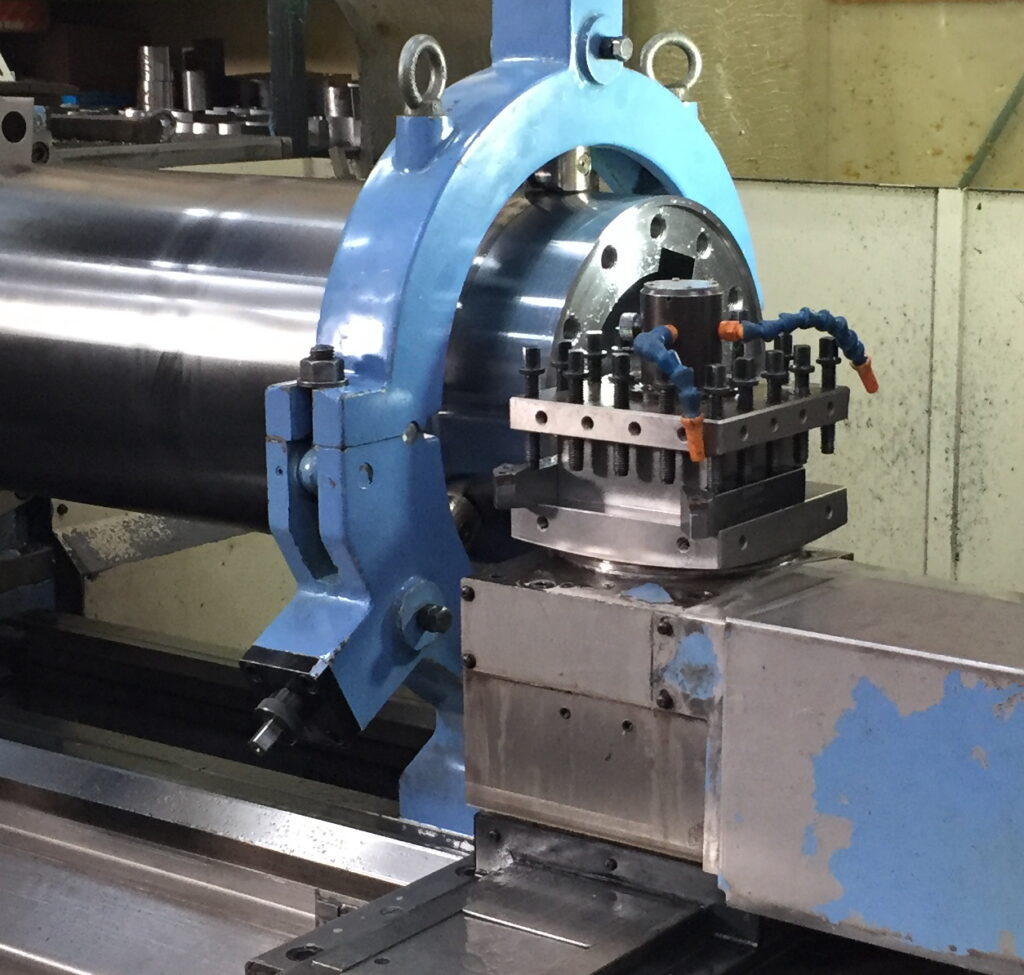

Here are free images from a job where we performed JIS Class 1 thread grinding on a machine tool spindle.

When machining a JIS Class 1 thread, it’s crucial to consider not only the thread’s accuracy but also the concentricity of the workpiece and the fit with the mating internal thread. Selecting the right grinding wheel and cutting fluid is essential, as these choices must be tailored to the workpiece.

Furthermore, the threaded section is highly susceptible to damage; even a small dent can be fatal. Since thread grinding is often the final process, careful handling is required during machine setup, removal, and transport.

Key Terminology for the Article

- Thread grinding machine:A thread grinding machine holds a workpiece with high precision between centers on both the headstock and tailstock. The workpiece rotates via a lathe dog, driven by the headstock’s motor, and a high-speed rotating grinding wheel shapes the threads.

To complete a high-precision thread, the workpiece is fed with an accurate lead while being finished and measured with a three-wire gauge or thread gauge. - Class 1 thread:A Class 1 thread is a screw thread grade from the former JIS (Japanese Industrial Standards). It refers to a thread that requires relatively tight tolerances. These threads are used for parts in precision machinery where high accuracy is essential.