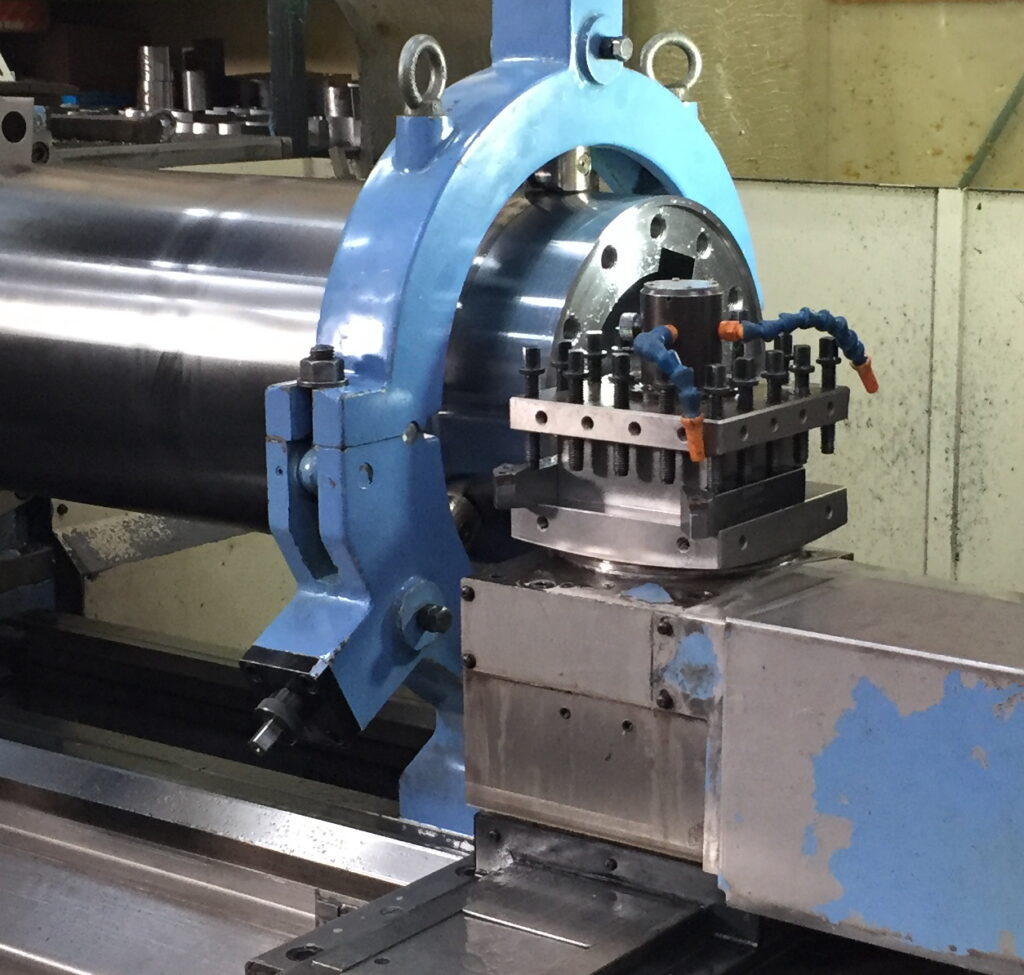

This is a free image of a CNC lathe machining the inner diameter of a cylinder using an anti-vibration boring bar.

For long cylinders, it’s common practice to machine from both sides with a shorter tool overhang to ensure rigidity. However, to achieve higher precision (concentricity, straightness, and dimensional accuracy) and avoid a joint mark, the entire inner diameter may be finished in a single pass from one side with a longer tool overhang.

In such cases, an anti-vibration boring bar is used to suppress chatter and vibrations that can occur during the machining process.

Key Terminology for the Article

- CNC lathe:A CNC lathe is a machine that uses a chuck to hold a workpiece and a tool post to hold a cutting tool, moving them according to a program to cut materials like metal. CNC stands for Computerized Numerical Control.

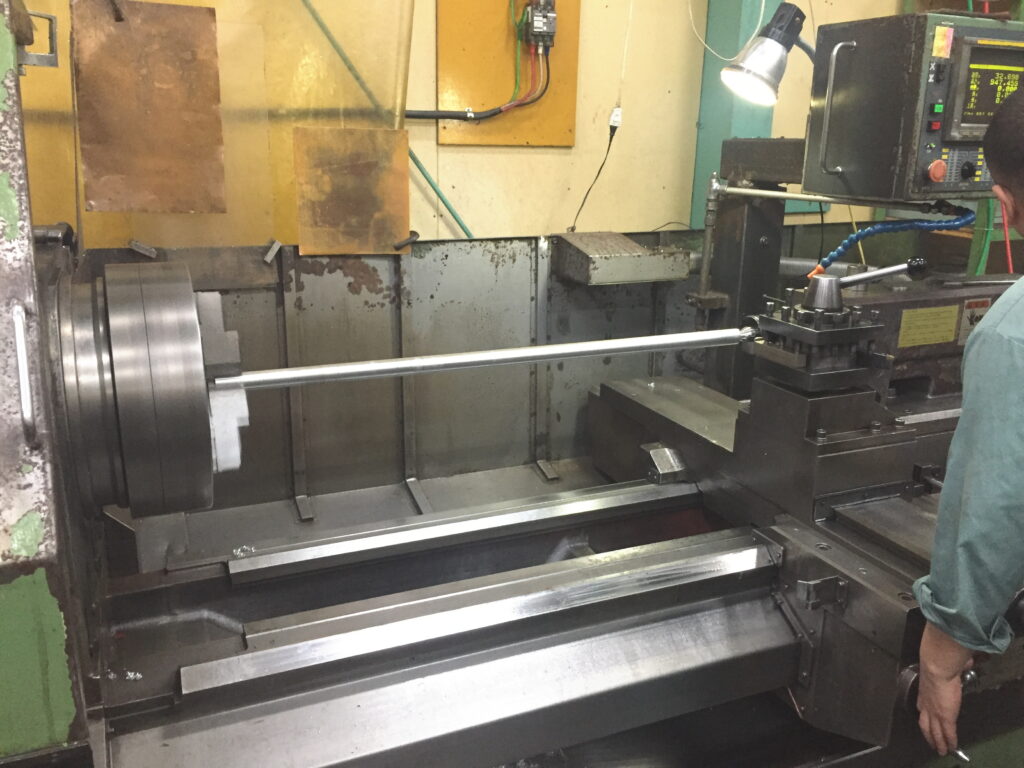

Compared to a general-purpose lathe, a CNC lathe offers a higher degree of automation and can machine more complex shapes. However, it is also possible to operate and machine with a CNC lathe manually, much like a general-purpose lathe. - Finishing:Finishing is the process of achieving the final dimensions and surface accuracy of a product.

At this stage, a small amount of material is removed with fine tools and good cutting conditions to ensure a high-quality surface finish and tight dimensional accuracy. Since mistakes during the finishing process are more costly and time-consuming to fix than in other stages, this step is performed with great care. - rigidity:Rigidity is the property that indicates how resistant a machine, tool, or workpiece is to deformation when a force is applied.

In any machining process, not just turning, low rigidity can cause the tool or workpiece to bend during cutting. This leads to inaccurate dimensions and can cause chatter, which damages both the workpiece and the tool. Long, thin shafts (especially in the center) are particularly prone to low rigidity, so special consideration and techniques are needed when machining them. - chatter:Chatter is a phenomenon where the tool or workpiece vibrates during the cutting process.

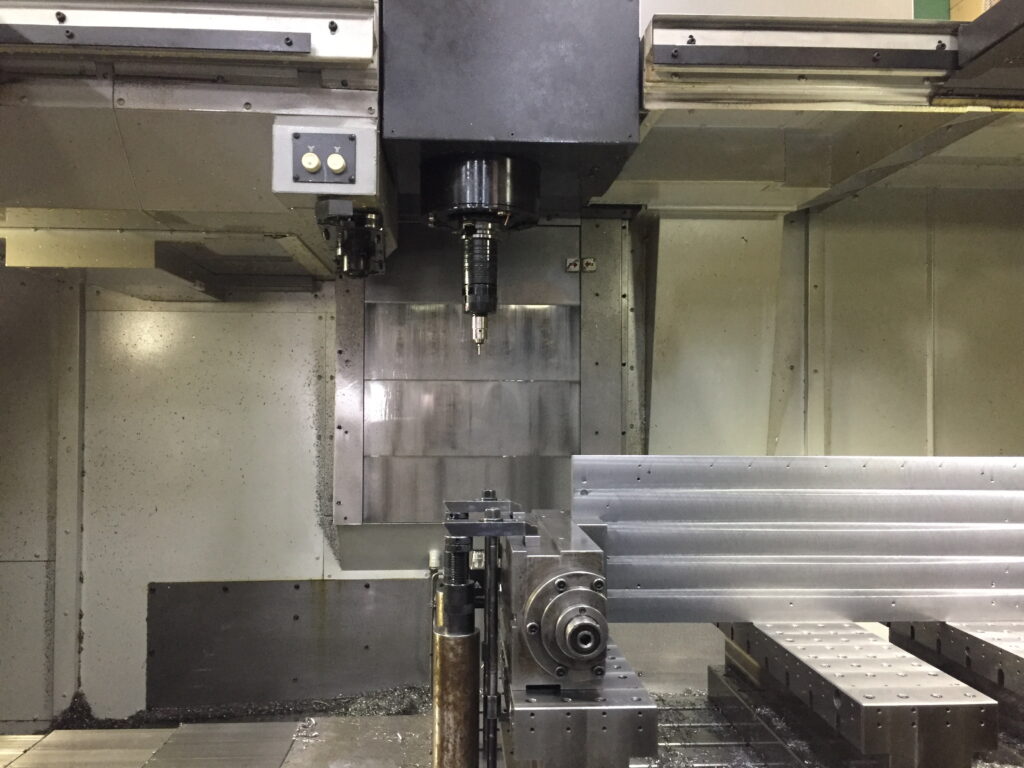

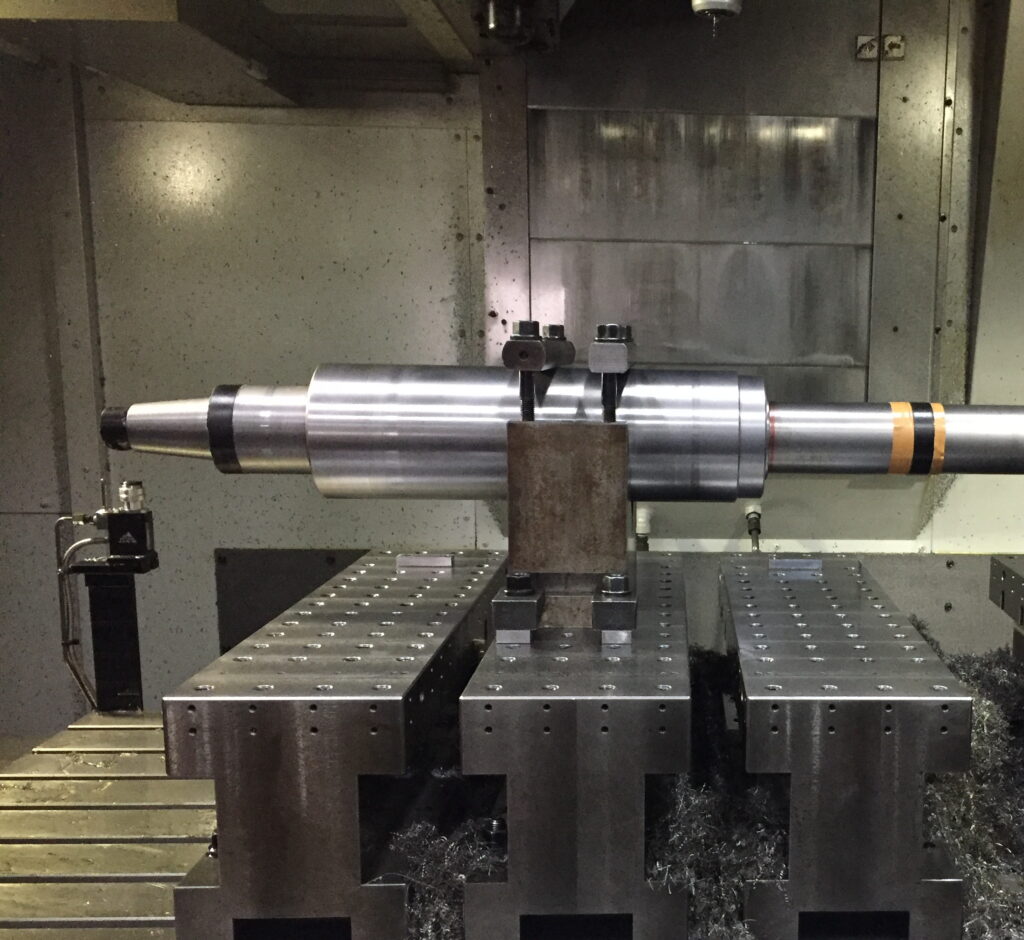

These vibrations can negatively affect the surface finish of the part, create an abnormal noise, and shorten the lifespan of the tool. Chatter is especially likely to occur when machining long, thin shafts or using long, slender cutting tools, so extra care is needed in these cases. - machining_from_both_ends:Here are some free images of the finishing process for a long, slender shaft with low rigidity on a CNC lathe.

For roughing, we shorten the overhang of the workpiece to increase rigidity and improve machining conditions. For finishing, we take care to prevent chatter in the central area. If the drawing allows for it, we will use a machining from both ends process to avoid unnecessary stress on the part.