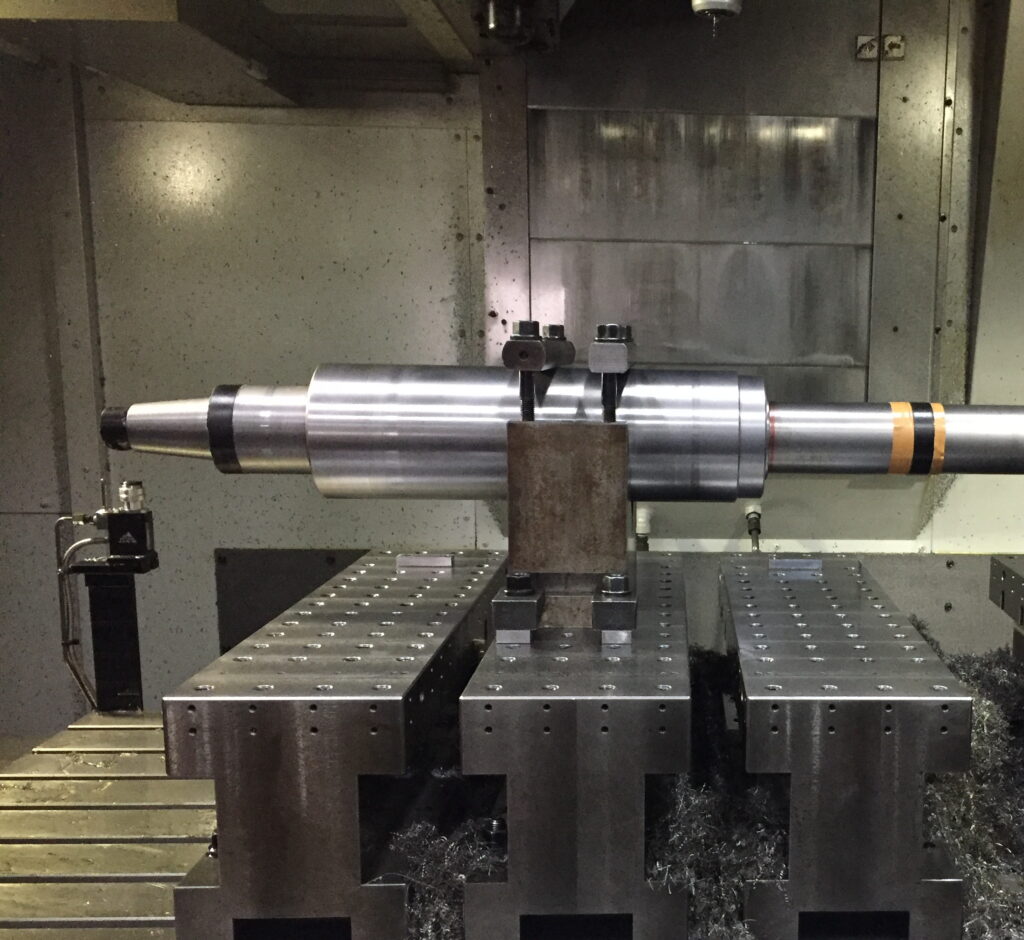

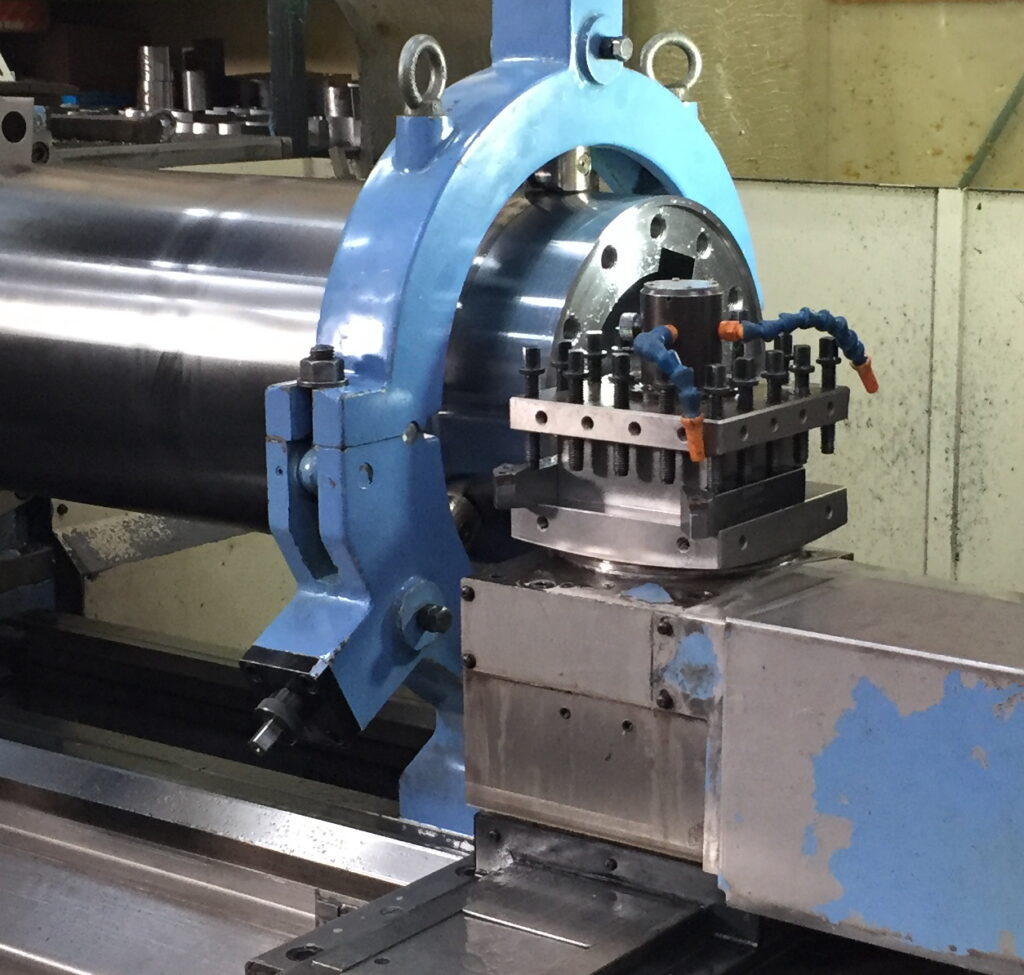

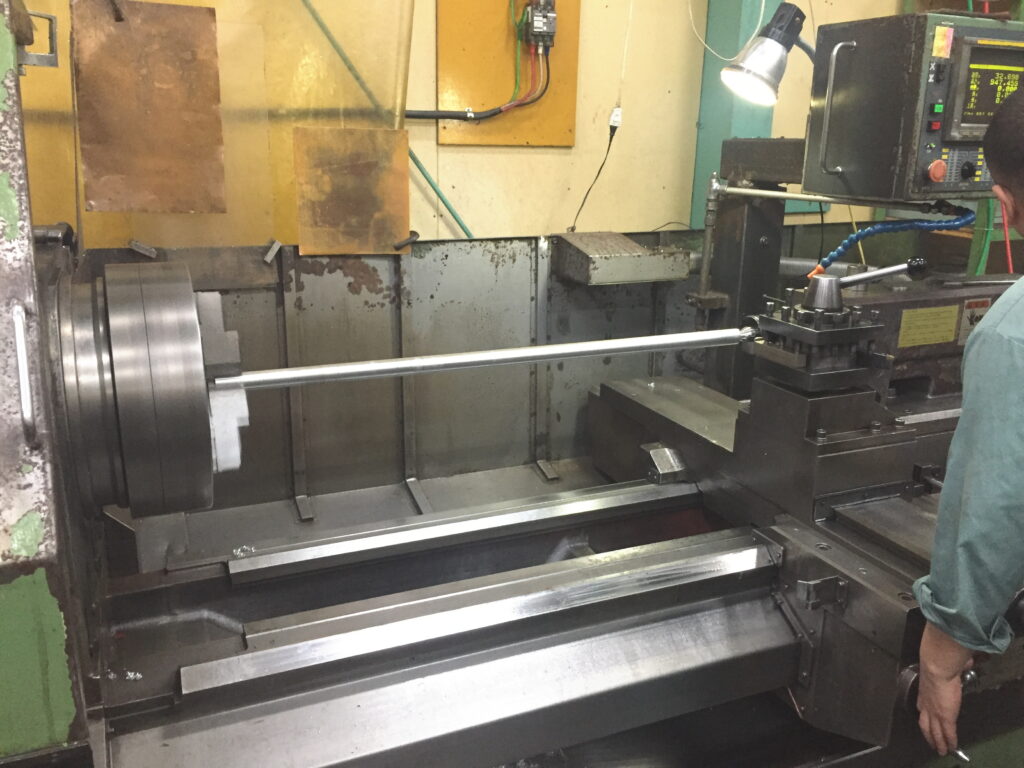

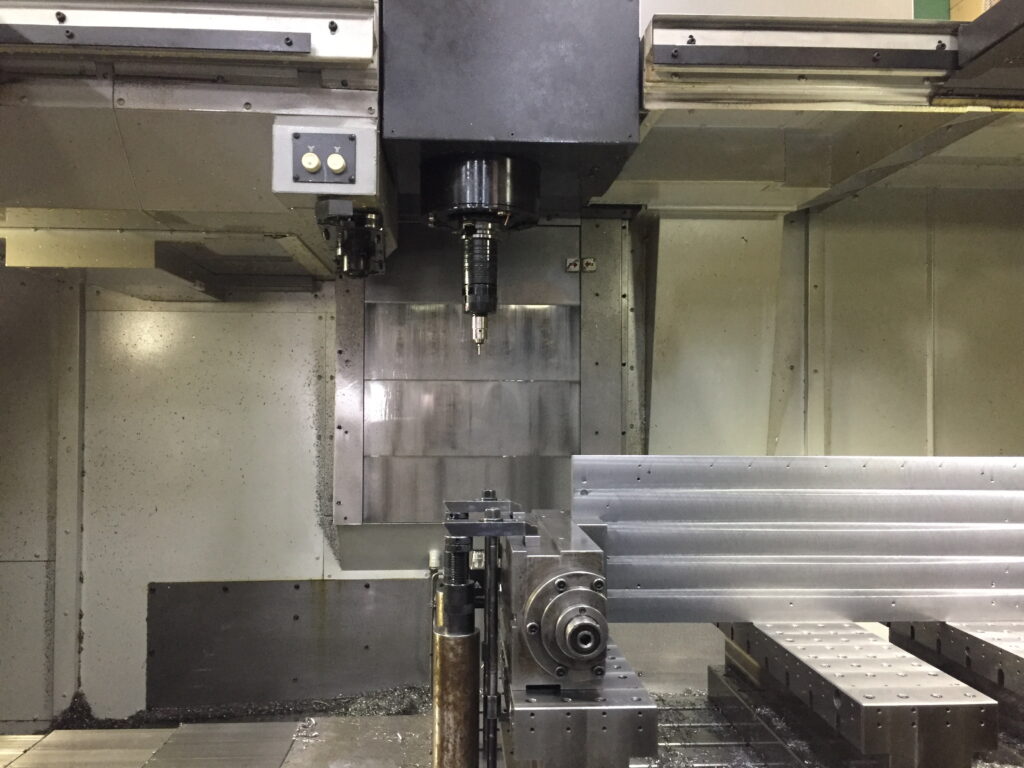

Here are some free stock photos of a vertical machining center, showing the setup for drilling holes in an S45C steel plate. The plate is clamped vertically using a vise.

While it’s crucial to align the vise itself, we always double-check the alignment directly on the workpiece after clamping. Also, since the plate is thin, there’s a risk of chattering near the center, so extra care is needed.

Key Terms and Explanations

- S-45C:This is a type of general-purpose rolled steel for machine structural use, often referred to as S-C steel. Containing approximately 0.45% carbon, this carbon steel is relatively easy to machine and has high strength and hardness. Because it is easy to heat treat with processes like quenching and tempering, it is a versatile material widely used for machine parts that require high durability.

While it is easy to work with, it is important to note that the material can become locally hardened from heat generated during the machining process, such as from welding or friction caused by a dull tool. - machine vice:A machine vice is a high-precision, heavy-duty vise that is mounted to the table of a machine tool, like a milling machine or machining center. By turning a handle, it clamps down on the material to hold it securely in place during a machining operation.

Its primary role is to withstand the high cutting forces generated by the tool and keep the workpiece from moving. This strong clamping force allows for the safe and accurate execution of complex cutting operations, such as precision drilling, milling, and contouring.

However, a machine vice can be difficult to handle, as overtightening it can scratch the workpiece or shorten the life of the vise itself. - chatter:Chatter is a phenomenon where the tool or workpiece vibrates during the cutting process.

These vibrations can negatively affect the surface finish of the part, create an abnormal noise, and shorten the lifespan of the tool. Chatter is especially likely to occur when machining long, thin shafts or using long, slender cutting tools, so extra care is needed in these cases. - machining center:A machining center is a type of CNC (Computerized Numerical Control) machine tool that machines material by rotating a cutting tool on its spindle.

It can hold multiple tools at once, allowing it to automatically perform various operations—such as drilling, milling, and tapping—in a single setup. By strategically arranging multiple workpieces on the machine, it is also suitable for continuous, unattended operation.