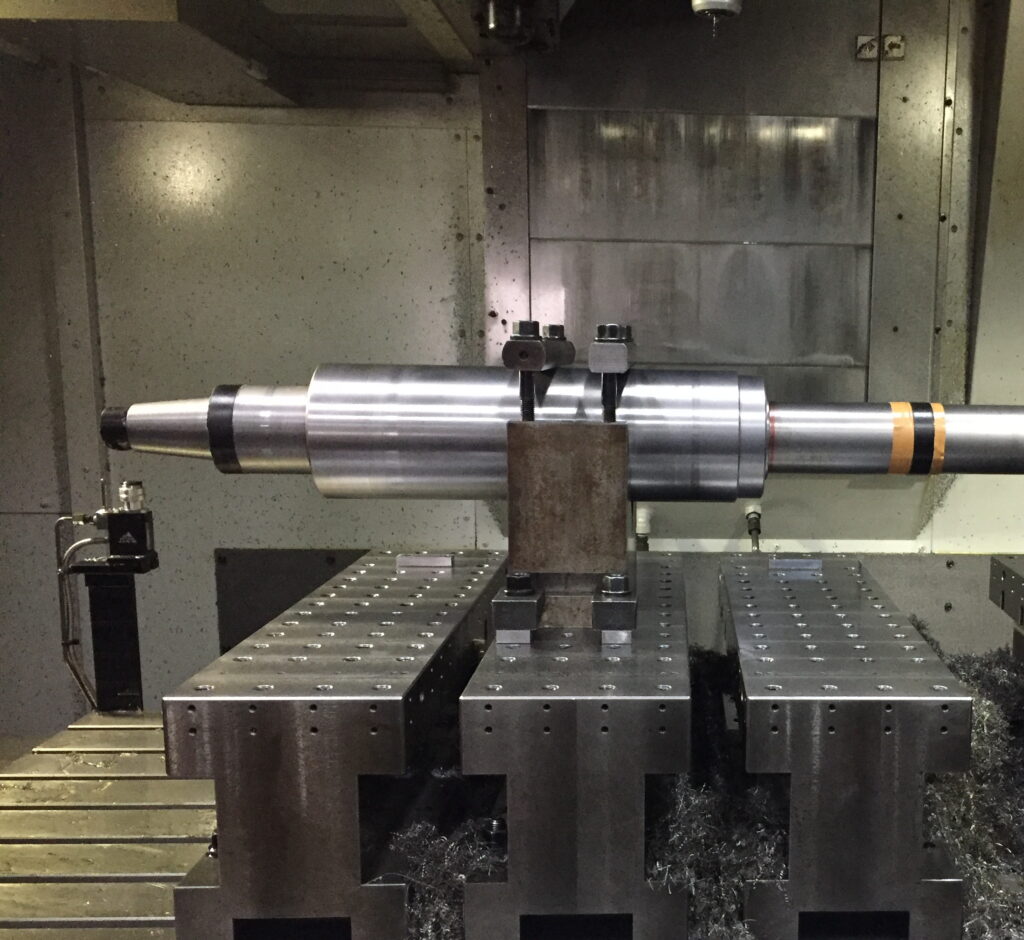

i’m setting up to machine a shaft on a large machining center, and I’m using a V-block to secure it.

V-blocks are ideal for holding cylindrical workpieces on a machine because they provide both precise positioning and strong clamping force.

The threaded section has already been finished, so it’s protected with tape.”

Key Terminology and Explanations

- machining center:A machining center is a type of CNC (Computerized Numerical Control) machine tool that machines material by rotating a cutting tool on its spindle.

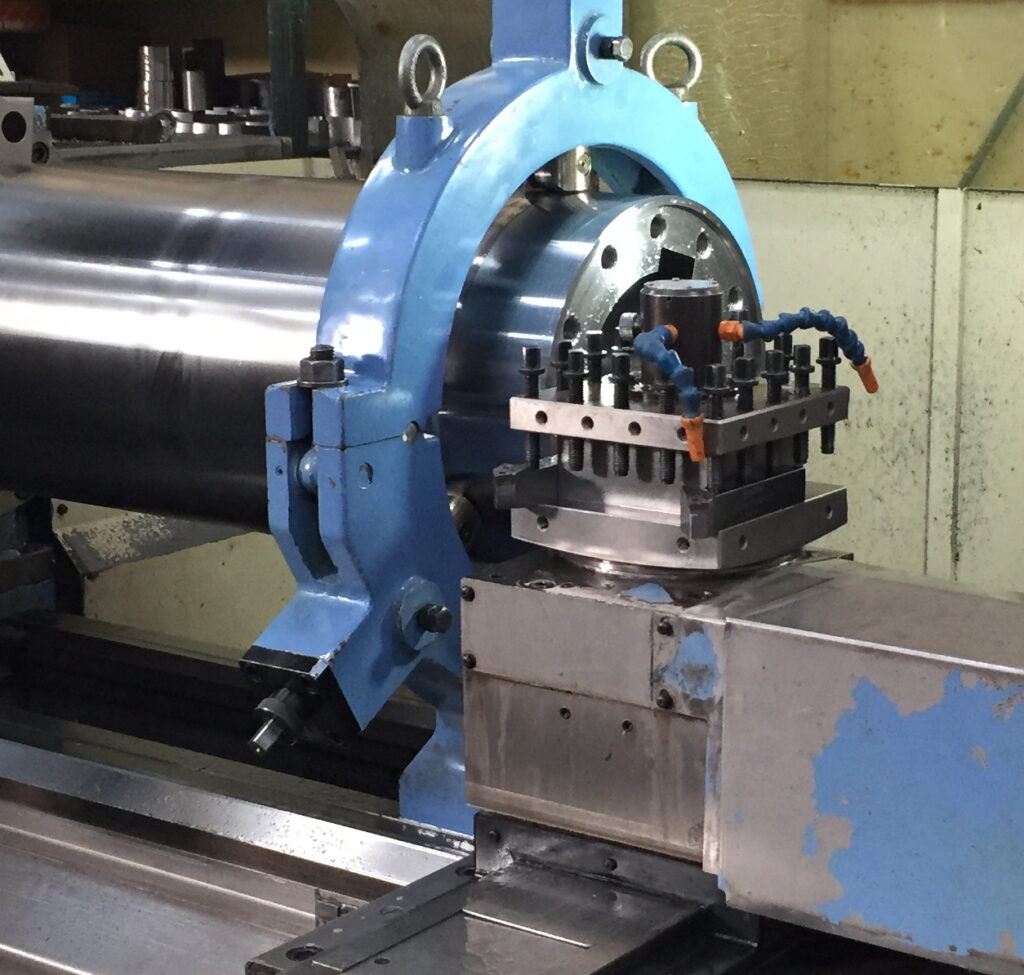

It can hold multiple tools at once, allowing it to automatically perform various operations—such as drilling, milling, and tapping—in a single setup. By strategically arranging multiple workpieces on the machine, it is also suitable for continuous, unattended operation. - V-block:A V-block is a block with a V-shaped groove used to accurately position and stabilize cylindrical workpieces.

The V-shape ensures that no matter where it contacts a cylindrical part, the center line of the part remains parallel to the base of the V-groove. This makes it essential for precision work like machining, inspection, and measurement.

Because of this property, V-blocks are widely used as a base (jig) for secondary operations on lathes or milling machines and for measuring the roundness or runout of a part. However, a key point to remember is that the line or point contact between the V-block and the workpiece makes the contact surface susceptible to scratches or deformation. Therefore, it is crucial to select the V-block material based on the workpiece material and to adjust the clamping force carefully. - Finishing:Finishing is the process of achieving the final dimensions and surface accuracy of a product.

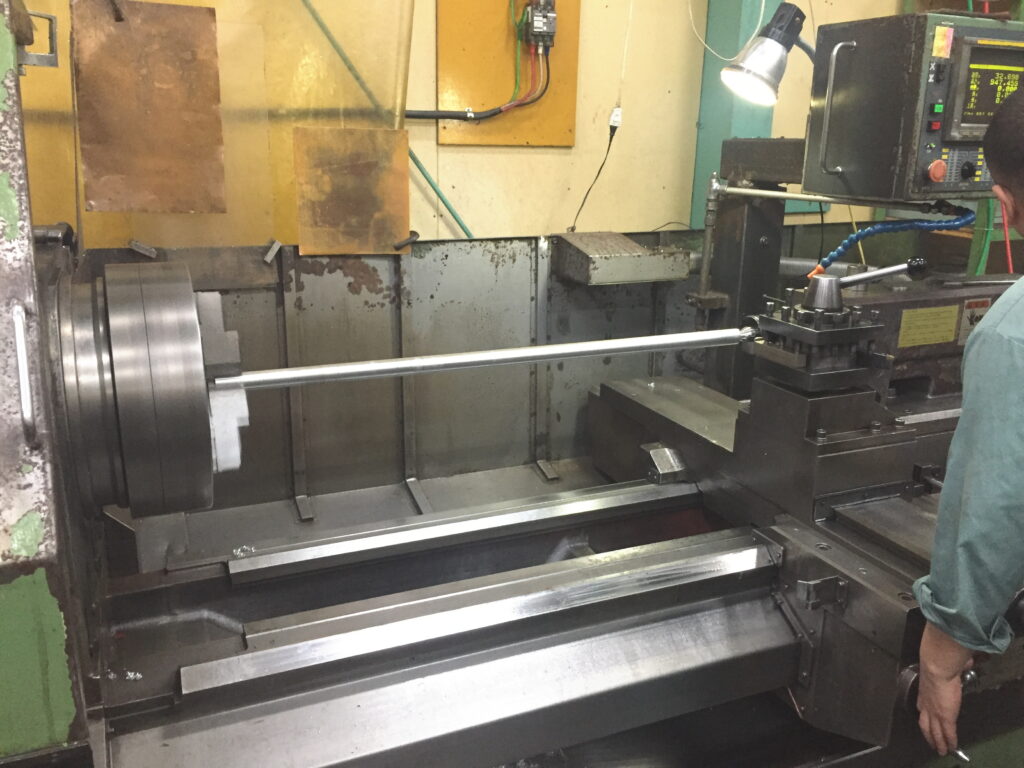

At this stage, a small amount of material is removed with fine tools and good cutting conditions to ensure a high-quality surface finish and tight dimensional accuracy. Since mistakes during the finishing process are more costly and time-consuming to fix than in other stages, this step is performed with great care. - machine vice:A machine vice is a high-precision, heavy-duty vise that is mounted to the table of a machine tool, like a milling machine or machining center. By turning a handle, it clamps down on the material to hold it securely in place during a machining operation.

Its primary role is to withstand the high cutting forces generated by the tool and keep the workpiece from moving. This strong clamping force allows for the safe and accurate execution of complex cutting operations, such as precision drilling, milling, and contouring.

However, a machine vice can be difficult to handle, as overtightening it can scratch the workpiece or shorten the life of the vise itself.