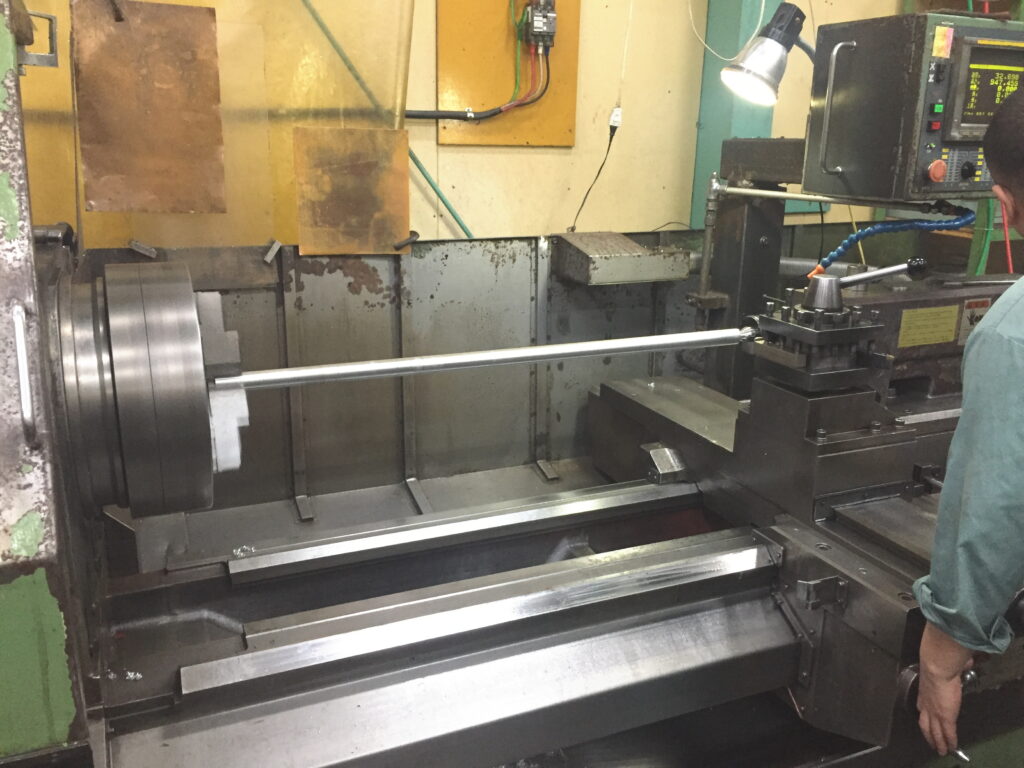

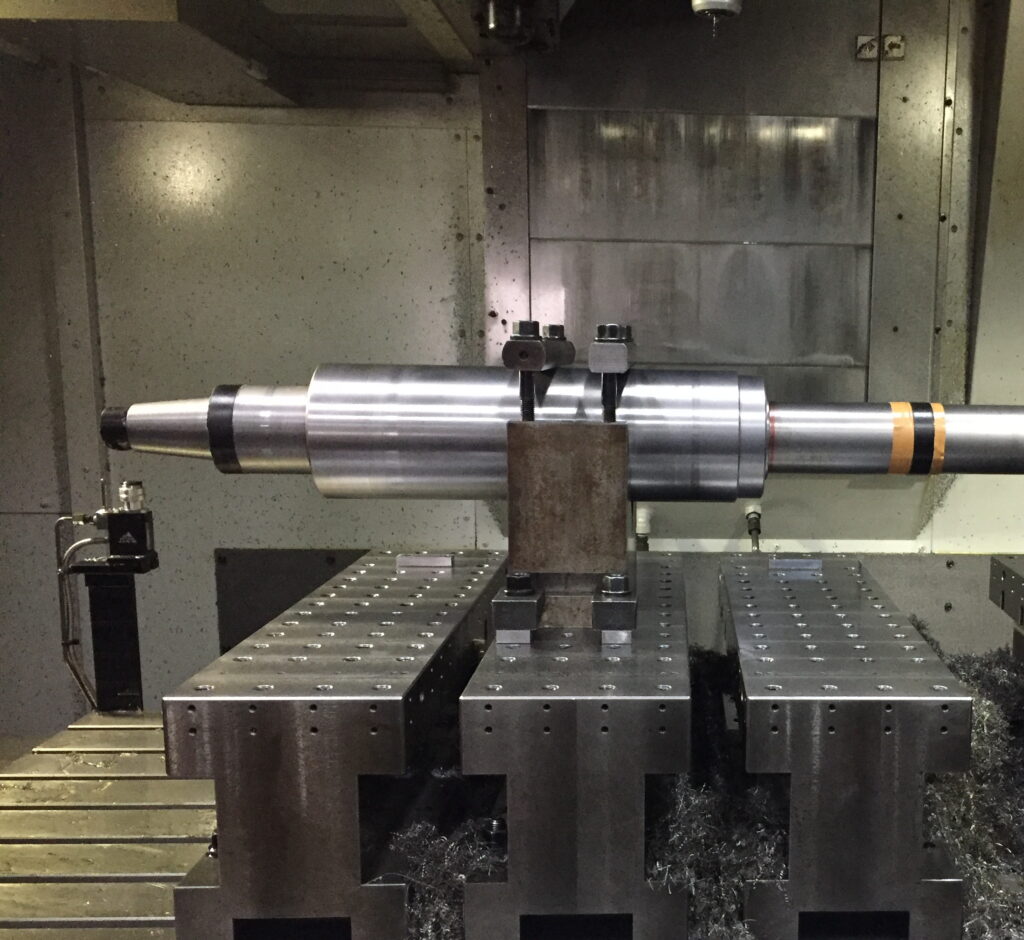

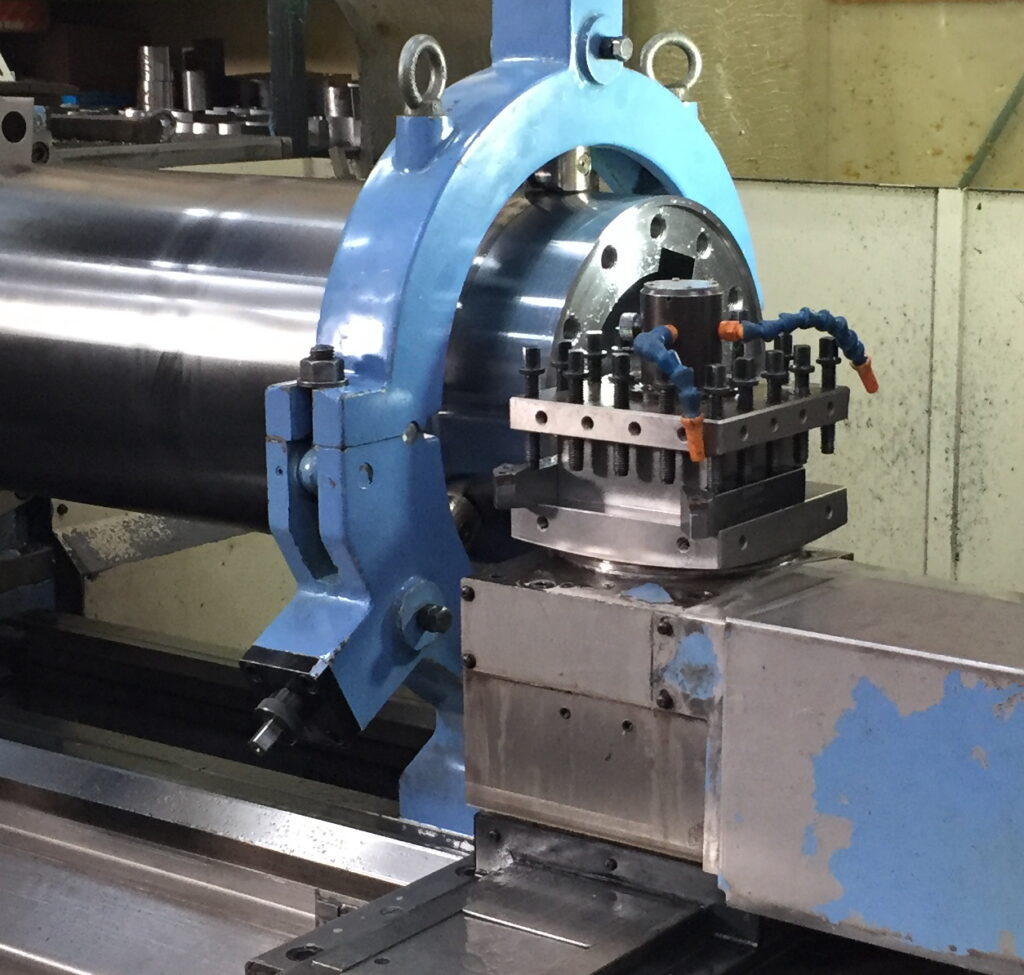

Free image of blade machining for a screw pump using a 5-axis CNC center and stainless steel disc material.

Due to the properties of stainless steel, precision machining requires careful attention to heat generation and tool wear. In this process, rather than using dull-angled throwaway inserts, a sharp end mill was selected to perform trochoidal (slice) cutting. This method helps minimize heat buildup during cutting.

For coolant, a highly penetrative and thermally efficient strong alkaline ionized water was used. This fluid offers several advantages:

- High pH (~12) prevents bacterial growth, reducing the risk of spoilage and extending fluid replacement cycles.

- Excellent penetration and cooling performance help reduce tool wear and allow for more aggressive cutting conditions.

- Superior cleaning ability makes it easy to remove chips and residual coolant from the workpiece and machine.

Key Terminology for the Article

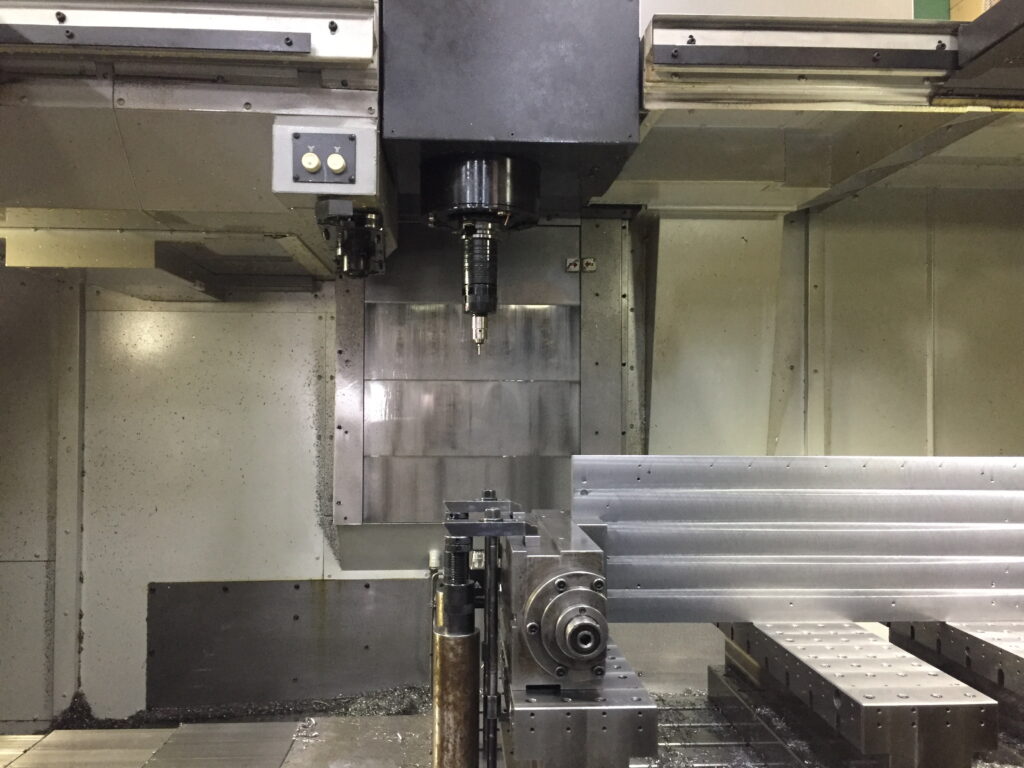

By having five axes, a workpiece can be machined from multiple faces with a single setup, significantly reducing setup time. This also makes it possible to efficiently machine complex-shaped parts with free-form surfaces that were previously difficult to produce.

Because of the mechanical structure of having five axes, they generally have lower rigidity compared to three-axis machines. This makes proper workholding and tool selection critical.

It is primarily used for machining complex 3D shapes, such as inclined surfaces and curved surfaces, that are difficult to create with standard tools. Because it processes horizontal outlines at a constant Z-level, it excels at machining near-vertical shapes but struggles with near-horizontal shapes, where the contour lines become spaced out, causing steps to form.

While some products are pure water-based with no additives like surfactants or organic solvents, others contain small amounts of additives to enhance their cutting performance and rust-prevention. This makes them widely used across various industries as both cleaning fluids and cutting oils.

It is recommended to store strong alkaline ionized water in a sealed container. This is because it can react with carbon dioxide (CO₂) in the air, causing its pH to drop and it to lose its effectiveness in cleaning and rust prevention.

By taking shallow radial cuts, the tool load is significantly reduced, which in turn suppresses heat generation. This not only extends tool life but also prevents thermal distortion of the workpiece.

Because the load on the machine and spindle is minimal, this method is ideal for high-efficiency machining on 5-axis machining centers with lower rigidity.