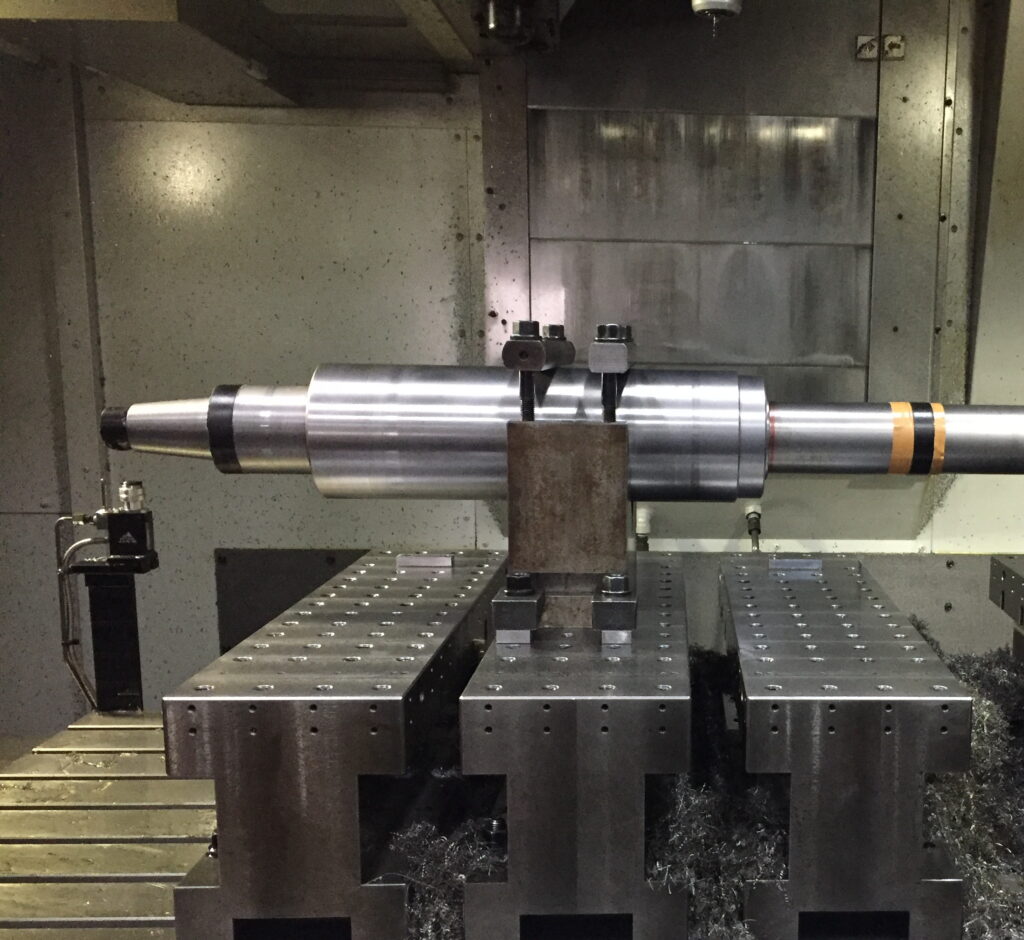

A free image of 5-axis contour roughing on a curved surface, performed with a radius end mill.

Contour machining is the go-to method for creating unique shapes like inclined or curved surfaces. For this process, a radius end mill is the ideal tool due to its resistance to corner wear and chipping.

Key Terminology for the Article

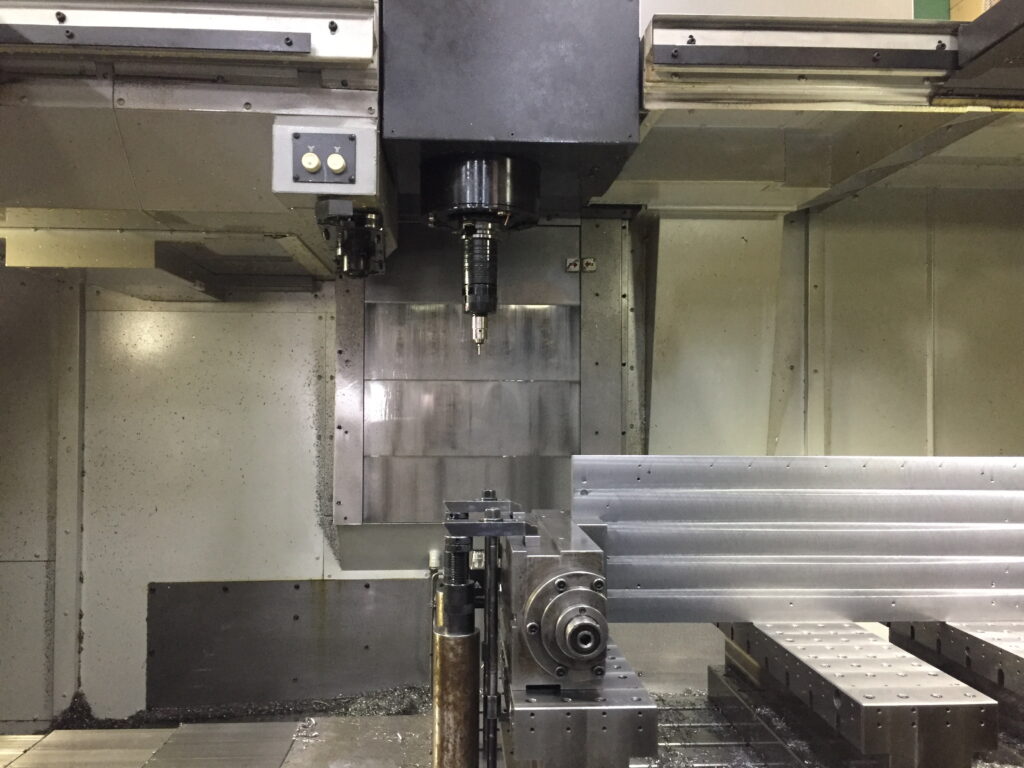

- 5 axis machining center:Five-axis machining centers are a type of machine tool that add two rotational axes to the three linear axes (X, Y, and Z) of a conventional three-axis machine.

By having five axes, a workpiece can be machined from multiple faces with a single setup, significantly reducing setup time. This also makes it possible to efficiently machine complex-shaped parts with free-form surfaces that were previously difficult to produce.

Because of the mechanical structure of having five axes, they generally have lower rigidity compared to three-axis machines. This makes proper workholding and tool selection critical. - Contour Machining:Contour machining is a method of processing a workpiece by following a series of horizontal outlines at a constant height (Z-axis) that match the shape of the part.

It is primarily used for machining complex 3D shapes, such as inclined surfaces and curved surfaces, that are difficult to create with standard tools. Because it processes horizontal outlines at a constant Z-level, it excels at machining near-vertical shapes but struggles with near-horizontal shapes, where the contour lines become spaced out, causing steps to form. - Radius End Mill:A radius end mill is a cutting tool with a rounded corner (radius) on the cutting edge, which is a common point of impact during machining.

They are used in a wide range of applications, such as adding a rounded shape to the bottom of a part, preventing tool breakage, and machining 3D shapes. Compared to square end mills, radius end mills are stronger and have a longer tool life. This difference becomes especially noticeable with longer tools, where deflection can easily occur.