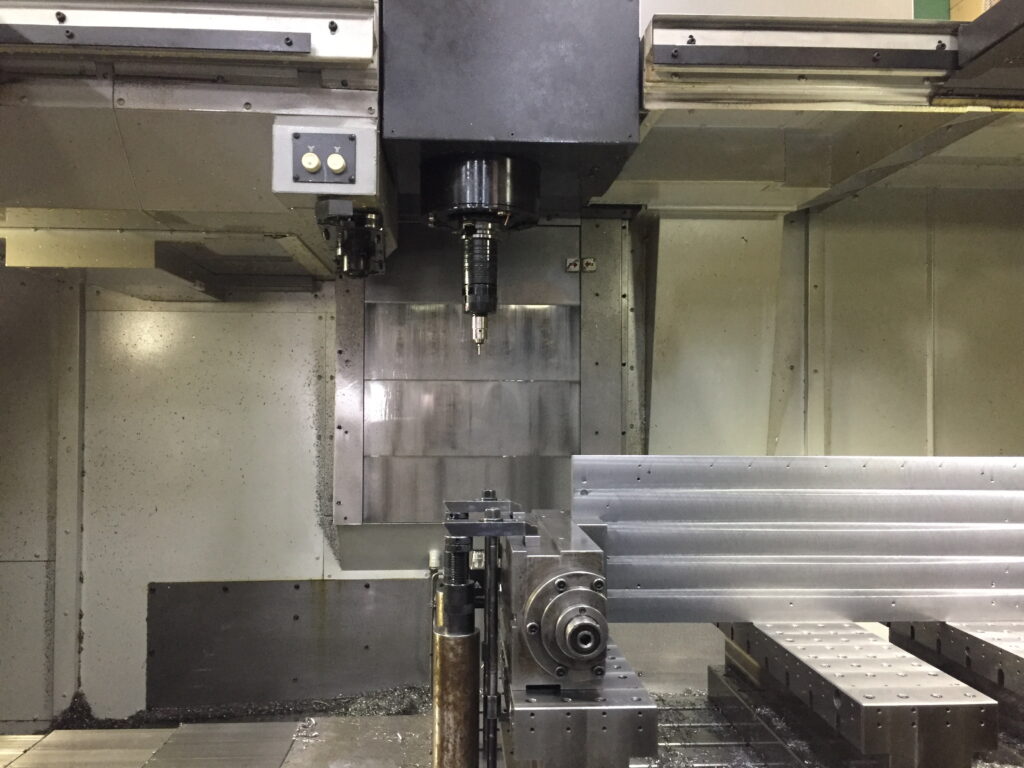

Here are some free images from a milling job we did using a CNC milling machine with a face mill and strong alkaline ionized water.

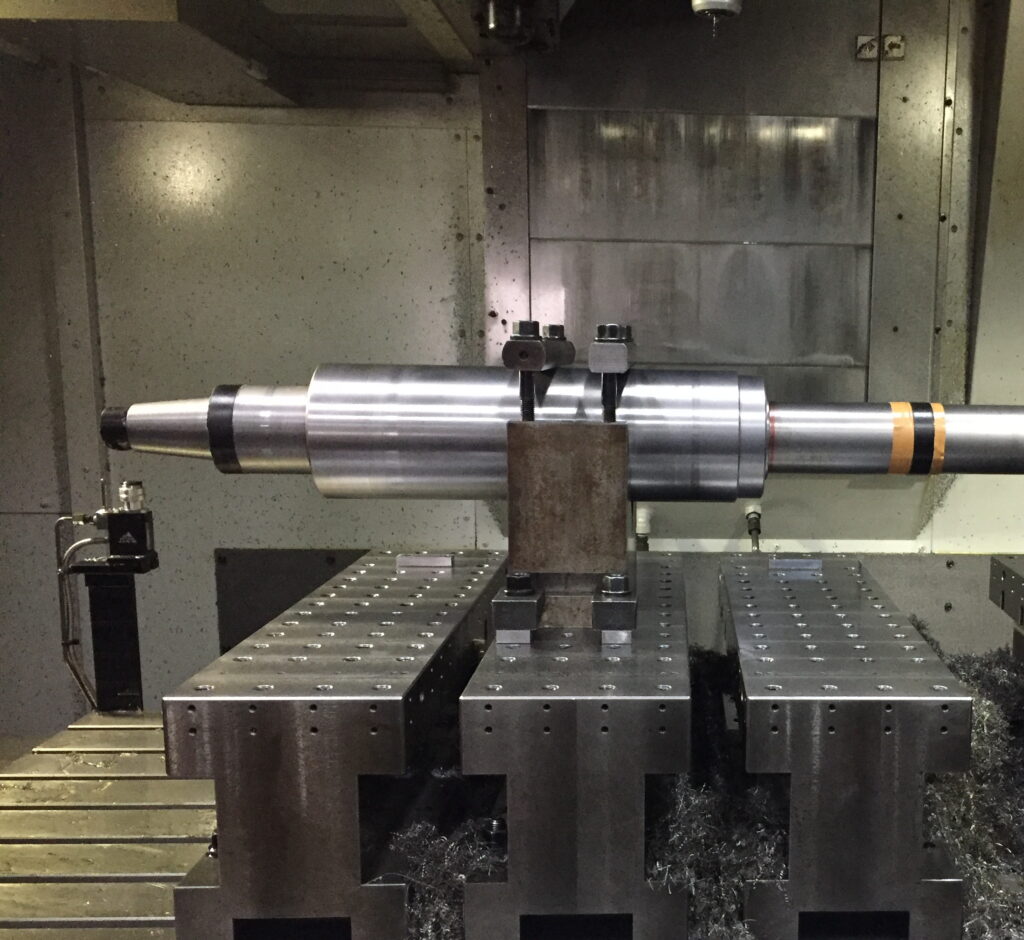

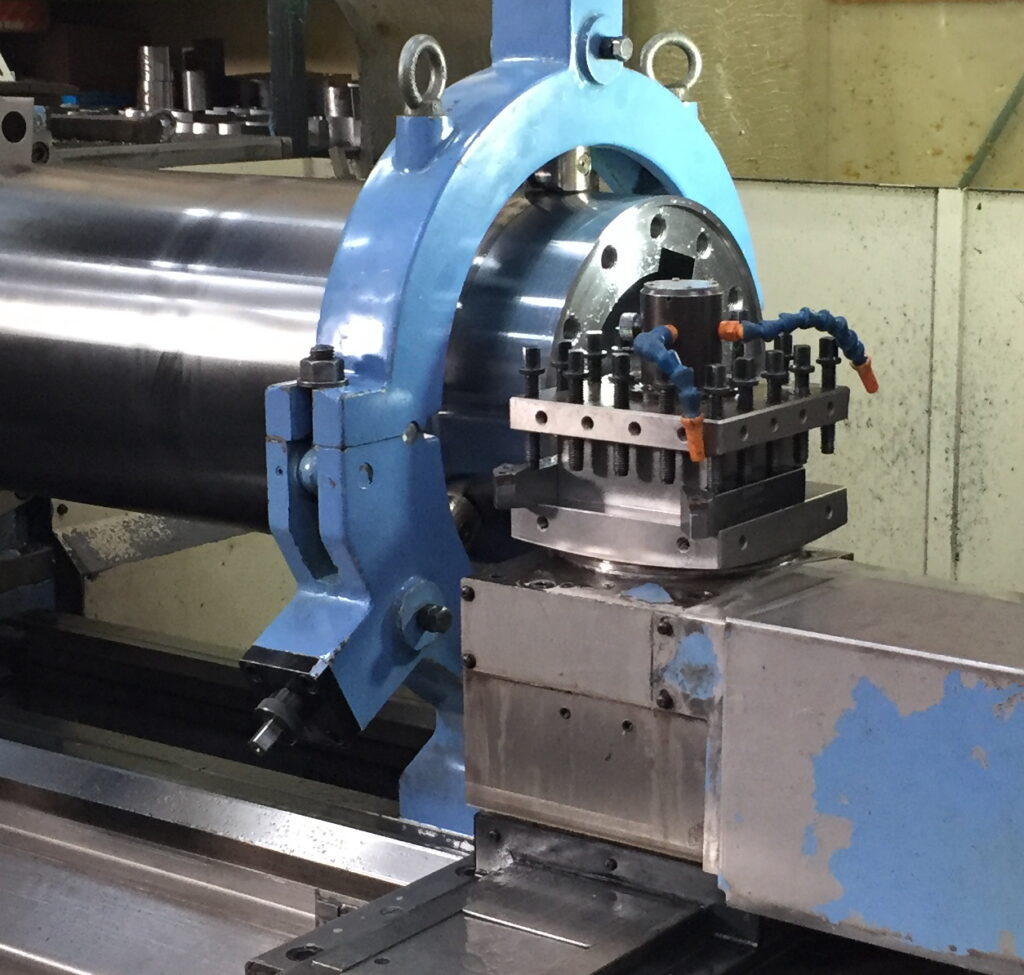

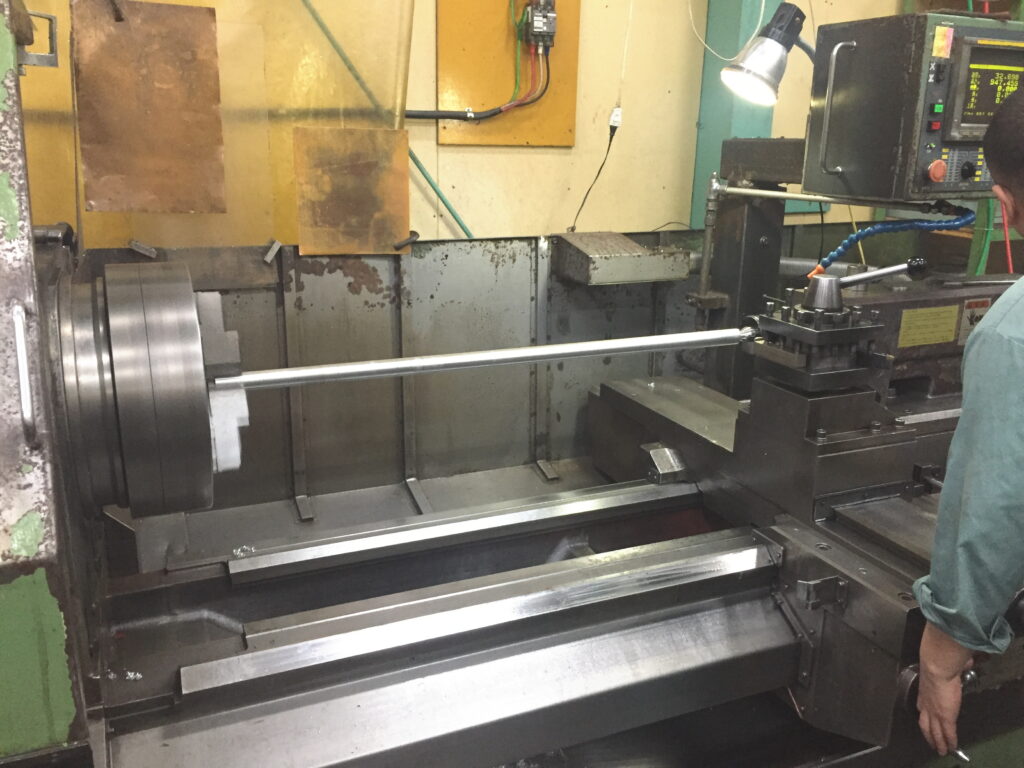

When machining long workpieces, we use multiple vises to secure them in a row. This prevents chatter and warping, ensuring a clean cut. For this type of job, we use sharp tools and a coolant with high cooling properties.

For this specific process, we used strong alkaline ionized water as the cutting fluid. Its benefits as a coolant are as follows:

- Improved Tool Life: Its high permeability and excellent cooling properties reduce tool wear, allowing for higher cutting speeds.

- Easy Cleanup: Its superior cleaning power makes it easy to remove cutting fluid and chips after the job is done.

- Longer Shelf Life: With a high pH of around 12, it’s difficult for bacteria to multiply in the fluid, preventing it from spoiling and extending its replacement cycle.

Key Terminology for the Article

Compared to a general-purpose manual milling machine, a CNC milling machine offers a higher degree of automation and can machine complex shapes. However, it can also be operated manually, just like a conventional milling machine.

While some products are pure water-based with no additives like surfactants or organic solvents, others contain small amounts of additives to enhance their cutting performance and rust-prevention. This makes them widely used across various industries as both cleaning fluids and cutting oils.

It is recommended to store strong alkaline ionized water in a sealed container. This is because it can react with carbon dioxide (CO₂) in the air, causing its pH to drop and it to lose its effectiveness in cleaning and rust prevention.