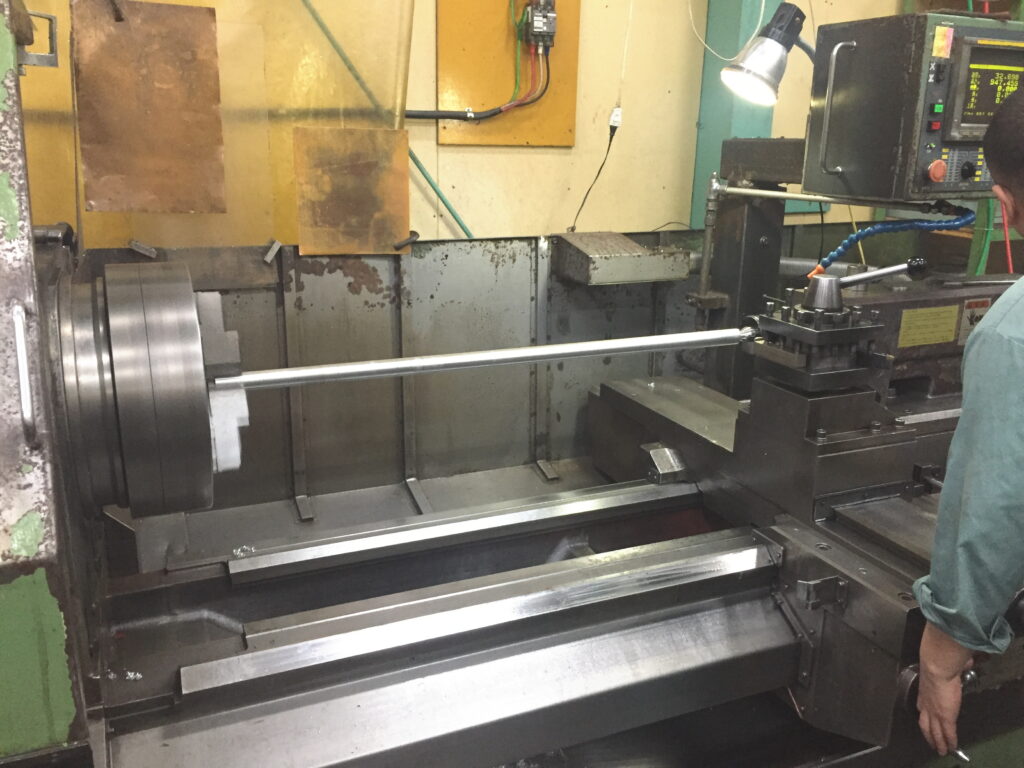

This is a free image of a CNC lathe finishing the end face of a cylinder using a steady rest.

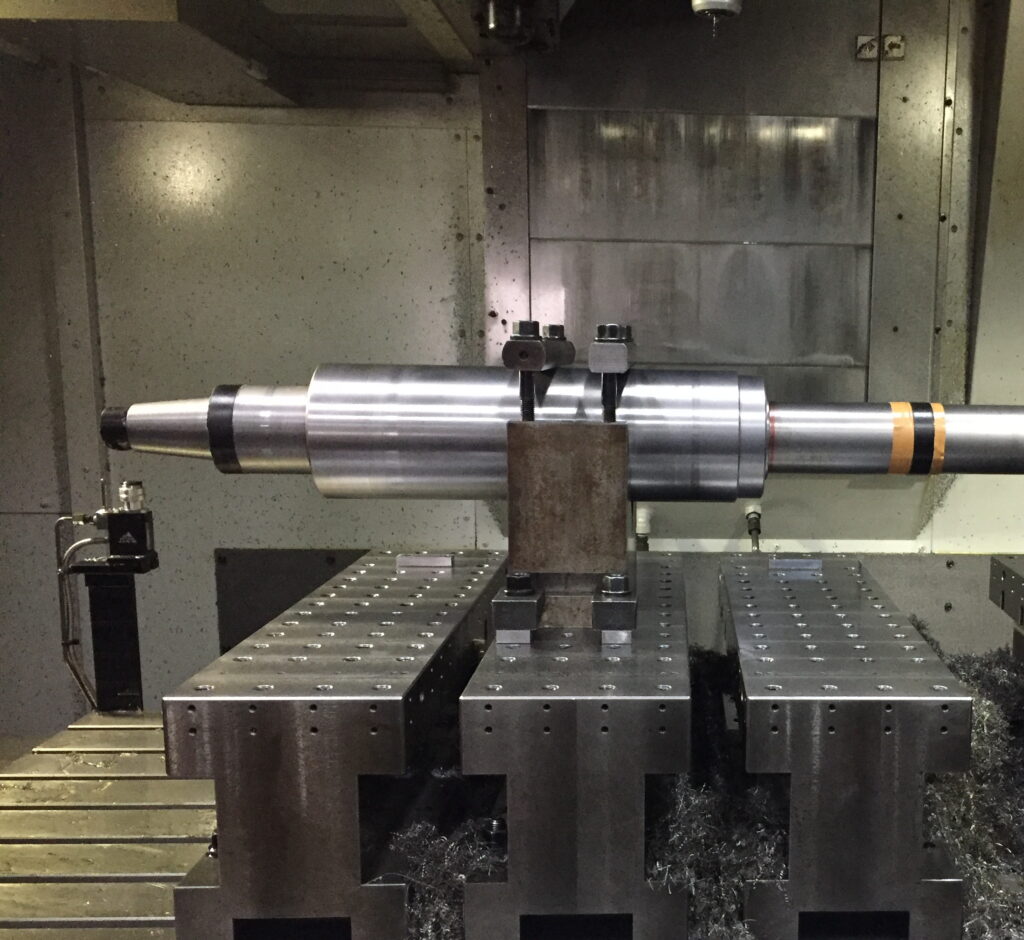

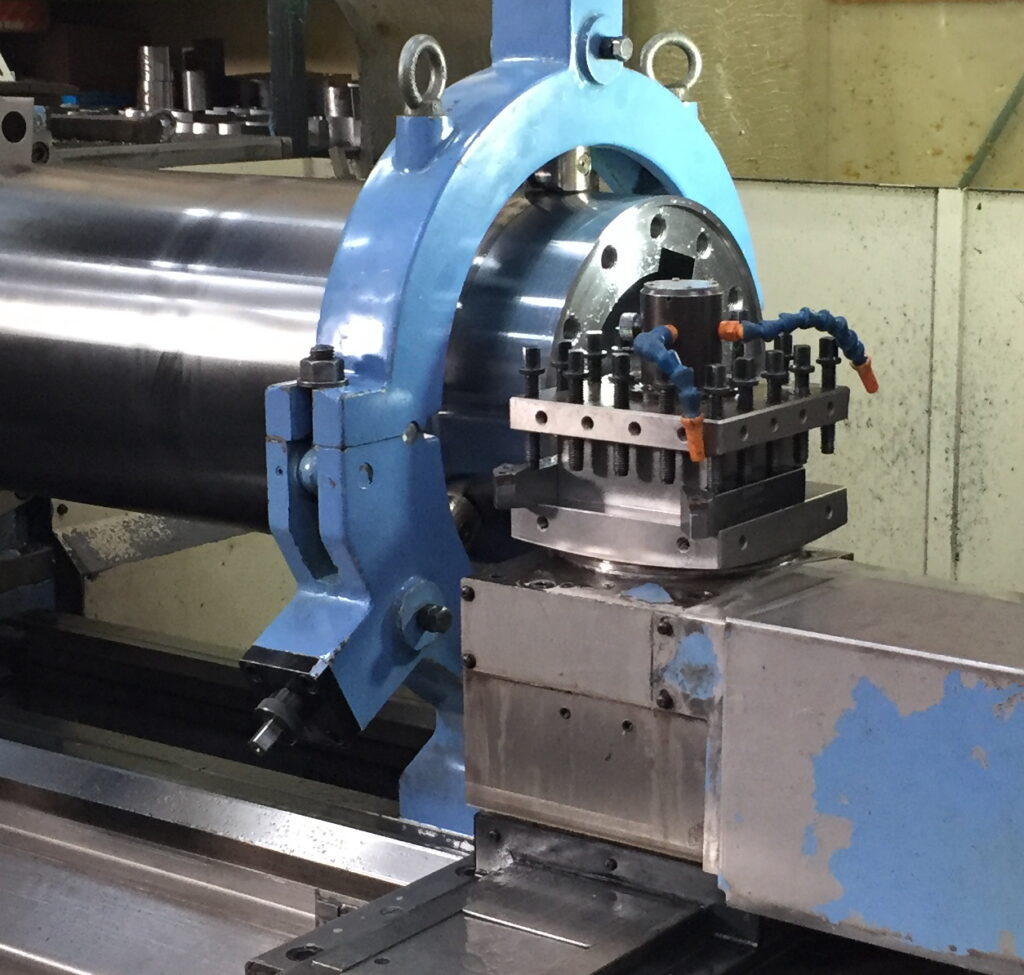

The workpiece is a difficult-to-cut material with a threaded hole and a keyway on the surface. For this reason, we had to dismantle the setup for the inner diameter work, reposition the steady rest near the end face, and increase the rigidity of the machining surface before the cut.

Key Terminology for the Article

- CNC lathe:A CNC lathe is a machine that uses a chuck to hold a workpiece and a tool post to hold a cutting tool, moving them according to a program to cut materials like metal. CNC stands for Computerized Numerical Control.

Compared to a general-purpose lathe, a CNC lathe offers a higher degree of automation and can machine more complex shapes. However, it is also possible to operate and machine with a CNC lathe manually, much like a general-purpose lathe. - Finishing:Finishing is the process of achieving the final dimensions and surface accuracy of a product.

At this stage, a small amount of material is removed with fine tools and good cutting conditions to ensure a high-quality surface finish and tight dimensional accuracy. Since mistakes during the finishing process are more costly and time-consuming to fix than in other stages, this step is performed with great care. - Steady rest:A steady rest is an auxiliary tool used on lathes and grinding machines to suppress deflection and vibration (chatter) when machining long workpieces. It ensures rigidity by supporting the outer diameter of the workpiece with three rollers.